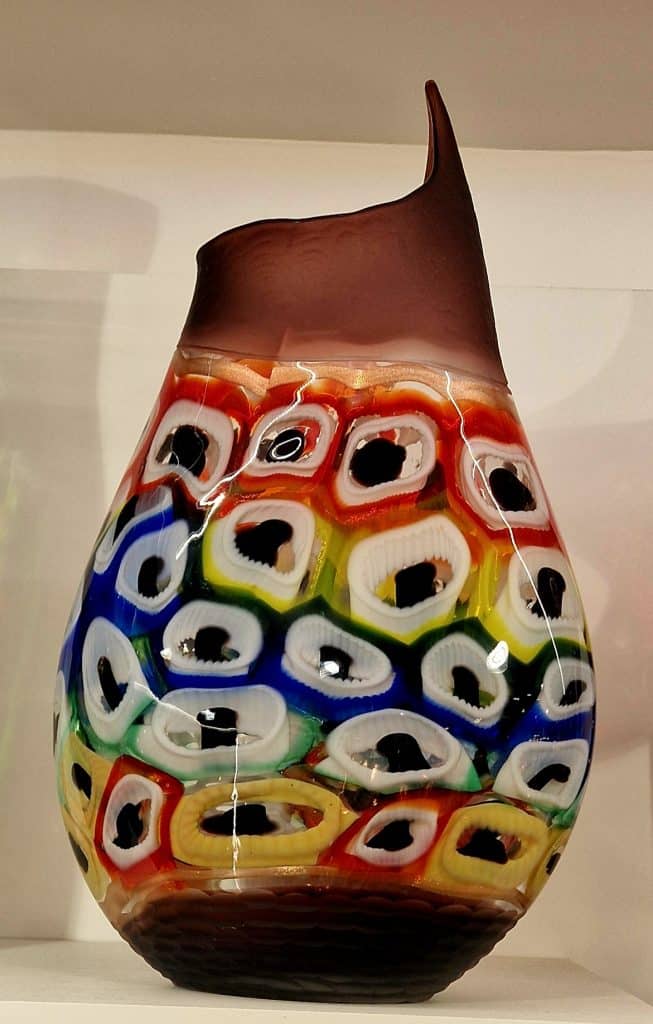

Murano glass is often admired for its colors and shapes.

Much less understood is what it actually takes to make them.

Behind every finished piece there is heat, weight, time — and a way of working that cannot be learned from books or videos.

It is learned inside the furnace, day after day.

This page exists to explain how Murano glass really works, from the inside.

🧪 Raw materials: sand, minerals, and fire

Murano glass begins with sand — but not just any sand.

Today, many furnaces rely on extremely pure silica, often sourced from places like Fontainebleau in France, chosen for its consistency and low impurity levels. In the past, Venice imported silica from the Eastern Mediterranean, including areas under Ottoman control, where the raw material was traded long before modern borders existed.

Color is not added casually.

It is created through mineral oxides, each reacting differently to heat:

- cobalt for deep blues

- manganese for dark tones and blacks

- iron for yellows and browns

- copper for greens and reds

The most complex and expensive color has always been red. Traditional Murano red relies on gold compounds, making it unstable, costly, and extremely sensitive to temperature changes.

Some historical opaline effects used substances that are now heavily restricted for safety reasons, which is why certain traditional looks can no longer be reproduced in the same way today.

🔥 The furnace: heat that never stops

A Murano furnace never truly rests.

Historically, furnaces were fueled by coal, then later by oil-fed systems, before transitioning to methane gas, which allows for more precise control. Each change altered not only efficiency, but the rhythm of work itself.

Inside the furnace are crucibles, separate containers holding clear and colored glass. The molten glass is gathered using a long metal pipe, becoming the starting point of every piece.

Electric furnaces exist, and they are excellent for glass fusing and controlled melting, but they are not suited for traditional hot working at the bench. Artistic glass shaped at the “scagno” requires flame, mass, and continuous heat in a way electric furnaces cannot provide.

🪑 The scagno: where glass takes shape

The scagno is the working bench where the glassmaker sits.

It is simple in appearance — and unforgiving in practice.

The pipe rests on the bench while the glassmaker rotates it continuously. Rotation is not optional. If it stops, gravity takes over: the glass begins to sag, proportions are lost, and the work collapses.

Glass must remain in constant motion to stay alive.

⚖️ Weight, leverage, and invisible effort

Many Murano sculptures are far heavier than they look.

The challenge is not only the weight, but where that weight sits. During work, the entire mass is held at the end of a metal pipe approximately 1.6 meters long. Heat travels quickly from the incandescent glass into the metal, making the first 30–40 centimeters of the pipe untouchable.

Not for the glass — for the hands that must keep turning it.

This forces the glassmaker to grip the pipe farther back, increasing leverage and strain. The weight is often off-axis, especially in complex forms, requiring constant correction.

At the same time, the glass must keep rotating.

Stop rotating, and gravity reshapes the piece instantly.

Working glass means sustaining heavy, unbalanced loads, away from the body, under extreme heat — while never losing control.

👥 A craft learned together

Murano glass is not made alone.

Complex pieces require a small team:

- a master glassmaker

- one or more assistants, traditionally called serventi

Assistants learn by helping. There is no shortcut. Skill is transmitted through observation, repetition, and physical memory.

Becoming a master glassmaker typically takes 10 to 20 years, depending on talent, discipline, and opportunity. Schools can introduce techniques, but only the furnace teaches the craft.

🎨 Working blind: color you cannot see

One of the least understood aspects of Murano glass is color.

When glass is malleable, it is incandescent — glowing orange.

Its final color is invisible during shaping.

Glassmakers work from experience and intuition, knowing how a color will emerge only after cooling. Every decision is made without seeing the result.

This is why Murano glass is not just shaped — it is anticipated.

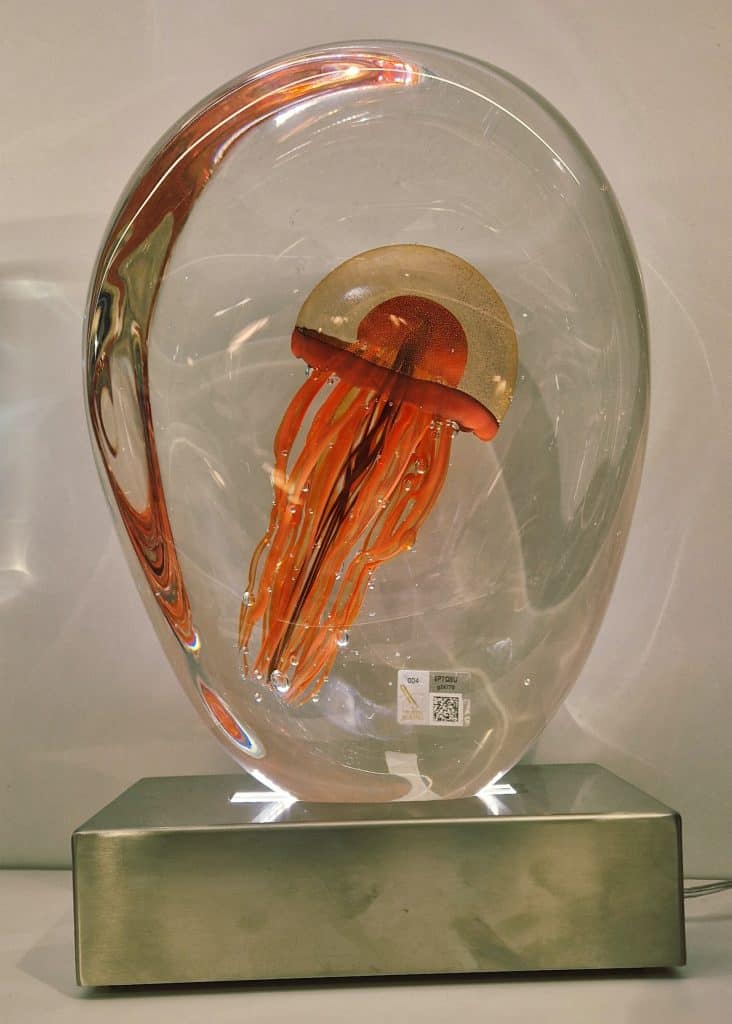

🧬 Uncontrollable beauty: Calcedonio

In the 15th century, Angelo Barovier developed one of Murano’s most extraordinary inventions: calcedonio glass.

By adding silver compounds to the melt, he created a material with marble-like veins and shifting colors. The reaction is inherently unstable. Patterns cannot be controlled or repeated.

Every calcedonio piece is unique — not by design, but by nature.

❄️ Cooling, tempering, and finishing

Once shaped, glass cannot simply cool in open air.

It must be tempered through controlled cooling to prevent internal stress that would cause cracking or shattering. This phase is as critical as shaping itself.

After cooling, pieces may undergo cold grinding and polishing, used both for refinement and decoration. These finishing techniques add precision, sharpness, and sometimes entire layers of ornamentation.

🧠 What Murano glass really represents

Murano glass is not just color and form.

It is:

- physical endurance

- long apprenticeship

- teamwork under heat

- decisions made without seeing the outcome

- materials that respond differently every time

Understanding Murano glass means understanding the process, not just the result.

And that process still happens, every day, inside the furnace.

I’ve worked with Murano glass for nearly three decades.

What I write here comes from daily work — not from books, brochures, or showrooms.

If you’re serious about Murano glass and want advice before buying, I’m often in the San Marco area.

You don’t need to buy anything.

Understanding comes first.

Back to the main guide: ✨Murano Island Venice — What to See + How to Visit

Continue exploring Venice:

🌊 Venetian Islands – Discover the Lagoon Beyond Venice

🌟 Hidden Venice: Fascinating Facts You Won’t Find in Guidebooks

🍽️ Traditional Venetian Food Guide: What to Eat in Venice (Local Insights)